Measurement while drilling (MWD) is a technology installed in the BHA and determines the position of the well by measuring the real-time parameters such as inclination, azimuth and tool face. These data help the directional driller to drill the well as the planned trajectory.

PKOK’s positive MWD systems with high-quality sensors allow for measuring data in any rough drilling environment.

Our MWD is used in the drilling process in oilfields. With the build-in sensors, also collects the real-time working status of the underground drilling equipment, well track and etc.

PKOK MWD transfers the collected information to the computer system on the ground via mud medium. The information provides the real-time guidance to drilling engineers.

We track the results of our operations in a comprehensive performance database. The database contains an extensive body of MWD knowledge and experience in all conditions including hard-rock which we use to optimize well placement and drilling performance. Our performance database also enables us to price our services fairly and competitively.

System Accuracy

- Azimuth accuracy: +/‐5 deg (0‐360)

- Inclination accuracy: +/‐05 deg (0‐180)

- Magnetic field accuracy: +/‐075 MT (0‐5T)

- Gravity tool face accuracy: +/‐5 deg (0‐360)

- Magnetic tool face accuracy: +/‐5 deg (0‐360)

Data Transmission

- Transmission Speed: 0.5 Hz, 0.8 Hz

- Survey Update: When pumps are cycled

- Toolface Updated: Every 14 seconds in 0.5 Hz transmission.

Every 8.75 seconds in 0.8 Hz transmission.

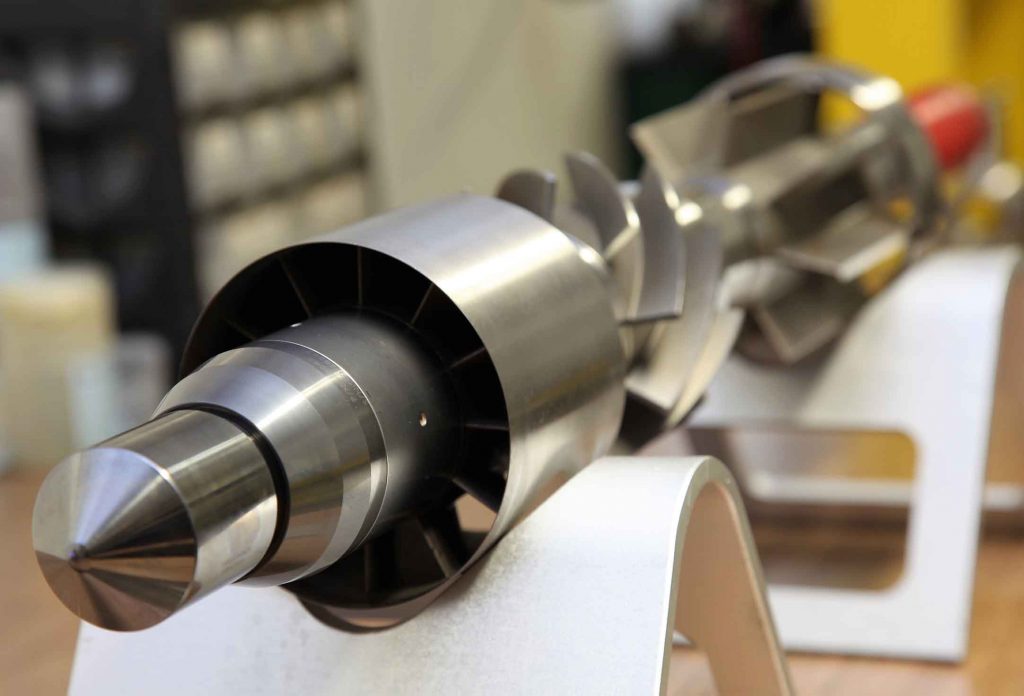

Downhole Tool

- Hole Size 4 1/8”~17‐1/2"

- Power source type Turbine pulser provides power to tools

- Mud pulse type Positive pulse

- Maximum Temperature 294°F (150°C)

- Working Pressure Up to 20,000 psi

- Mud weight Up to 160 PCF